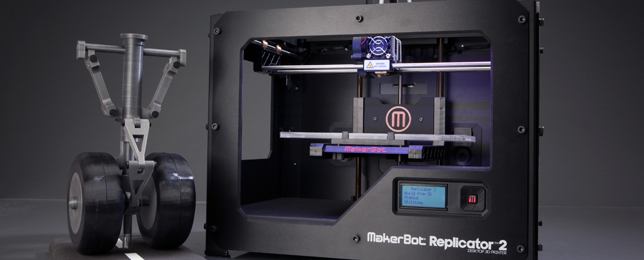

3D Printing and the automotive industry

Many of us will have heard of the amazing technology called 3D printing by now, it’s been around for a few years but the cost has made it prohibitive to all but those with very deep pockets. The astonishing speed at which this is being developed means that it is now becoming available to everyone and, whilst still rather pricey, competition between companies producing 3D printers is pushing prices down.

3D printers operate in a similar way to ink jet printers, but in 3D of course. The printer lays down layer after layer of liquid or powdered material to build the “printed” item and the detail achievable is quite incredible.

So does this mean that we can print our own replacement car parts? The simple answer is yes, we can, and a great deal more too! With a 3D scanner and a 3D printer it is possible to make a copy of practically anything, although it should be remembered that some copies may not be able to function in the same way as the original item because the materials used will be different. Plastic car trims are often stupidly expensive from main dealers, or they may even have become obsolete and difficult to source, this is the kind of item that can be easily and safely copied and if you don’t own a 3D scanner it is now possible to download the design and print it. If you don’t have a 3D printer there are companies popping up all over the internet where you can upload your 3D plans or choose from their library and they will print the item for you.

The technology of 3D printing is certainly impressive and it has infinite possibilities (can a 3D scanner and printer make a copy of a 3D scanner and printer?) but the safety and security issues raised by the capability of anyone copying and printing anything should be a matter of concern for all of us, it’s a terrifying reality that weapons will be copied as easily as car parts.

Special Thanks Creative Tools for providing the image